Choosing the Electric Chain Hoist that is right for you

Electric chain hoists are used for lifting and lowering loads in many different types of facilities. Choosing the right electric chain hoist plays a crucial role. It is important to consider a few key factors before selecting electric chain hoists for your operation:

- Required Capacity

- Frequency of use

- Height of Lift

- Lifting speed

- Availability and Voltage of power supply

- Safety Features

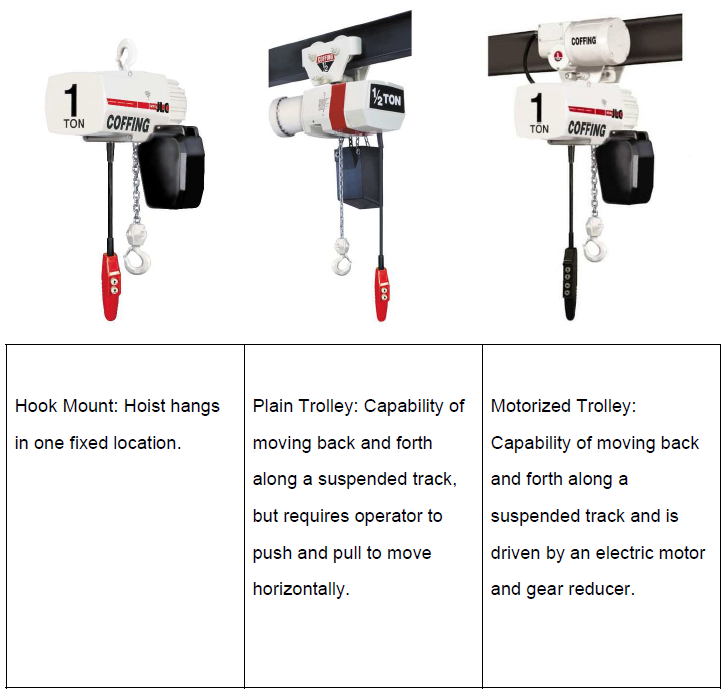

- Suspension type

- Environment

This is the most basic factor to consider but safety is paramount, so it's crucial to err on the side of caution. What is the weight of the heaviest load you are lifting? Remember to think about your current needs and possible future needs. A 4-ton chain hoist may be suitable to lift your items now, but what about down the road? Do you see yourself lifting heavier objects in the future than you are today? It's not cost-effective to upgrade frequently. Choose a hoist that accommodates both current and future requirements, ensuring it can handle heavier loads as your needs evolve.

Standard lifting capacities for light loads are 125kg, 250kg, 500kg, 1000kg, and 2000kg.

If your normal loads are 250kg and there's a chance you'll exceed that weight, opt for a 500kg capacity.

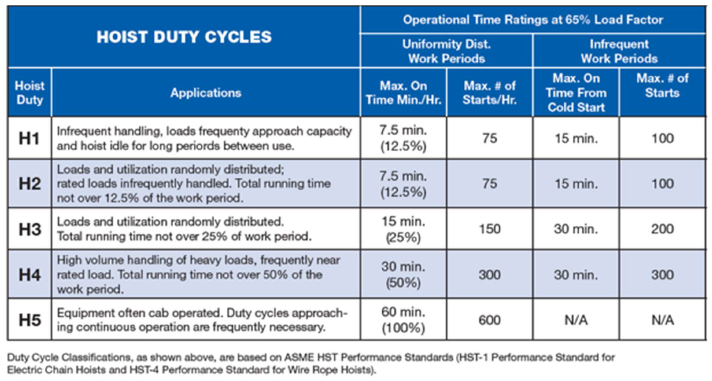

Consider how long the hoist will be running in a single 8 hour shift or minutes running per hour. Starts per hour and running time determine the Duty Cycle you will need for your hoist. This can range from 5 minutes per hour to continuous duty of 60 minutes per hour. Making the right choice here will determine the longevity of the equipment you are buying.

These duty classifications are based on numerous factors, including the number of lifts performed per hour over a given work period, the average and maximum load that is lifted, the frequency at which the maximum load is lifted, the average distance the load is raised and lowered, and the maximum number of stops and starts per hour.

The table shown below is provided for reference to help you understand the significance of duty class ratings provided by the hoist manufacturer for their products.

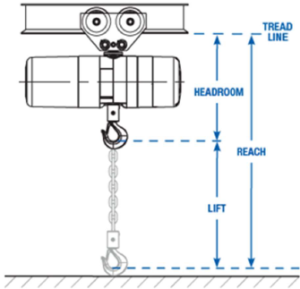

The height of the lift is the height from the lowest load level up to the beam or hoist. It is recommended to purchase electric chain hoists with enough lift for the hook to reach the floor. Take Headroom into consideration to ensure that your load can be raised high enough to clear any obstructions that may be in your work areas.

The lifting speed of a hoist is influenced by motor horsepower, gearbox ratio, and chain reeving. Electric chain hoists offer lifting speeds from as slow as 3 feet per minute up to 64 feet per minute. Higher horsepower motors can add to the size, weight and power consumption of a hoist, as well as its cost. If you are in a fast-paced production business, you might need faster electric hoists. Faster lifting speeds are preferred for long lifts or for shorter lift applications in which a high number of lifting/lowering cycles must be completed in a relatively short period of time.

Whereas, if your business requires less lifting and lowering of loads, then you'd need slow or medium-paced hoists.

Two speed hoists offer the flexibility for the operator to make use of a higher speed for movement or a slower pace for more precise placement of loads.

Choose a hoist with an appropriate lifting speed based on your operational needs to ensure optimal performance and productivity.

Keep your operators safe and protect your product and equipment from costly damage. Choose electric hoists with safety features such as load limiters, secondary brakes, chain containers and loading protection. It provides a safe and secure environment, minimizing damage and accidents to the workspace or to the employees.

Make sure that the structure where you are going to mount your hoist is capable of supporting your hoist and its load and has been certified by a Professional Engineer.

Make sure that the structure where you are going to mount your hoist is capable of supporting your hoist and its load and has been certified by a Professional Engineer.

Standard chain hoists are designed for "normal operating conditions." Conditions such as temperature extremes, unprotected outdoor areas, salt-laden marine environments, corrosive atmospheres, classified hazardous areas, clean rooms, and wash-down areas, among others, may require hoists with special modifications or optional features that are designed for those locations.

Conclusion

Choose the best for your lifting solutions!

We hope the information in this article provided insight into some of the considerations that should be taken before buying a hoist.

Selecting the right hoist for the application can be the first step towards safe, efficient and ergonomic movement of materials.

For further assistance with your overhead lifting requirements, please contact our application experts.